In recent years, Marble 3D wall paneling manufacturers have been at the forefront of transforming interiors with exquisite designs and textures. These manufacturers are introducing innovative techniques that make marble wall panelling not only an aesthetic addition but also a practical one. As demand for luxury interior solutions rises, homeowners and designers alike are turning to marble for its timeless appeal and durability. From creating textured surfaces to adding depth and character to walls, marble 3D panelling is becoming a defining trend in both residential and commercial spaces.

One of the major factors driving the popularity of marble 3D wall panels is their versatility. With the ability to be customized to fit any design aesthetic, they allow architects and interior designers to experiment with different shapes, sizes and finishes. Furthermore, the growing demand for eco-friendly materials has pushed manufacturers of marble 3D wall panelling to adopt sustainable practices, using responsibly sourced marble and environmentally friendly production methods. This combination of luxury and sustainability is making marble panelling an increasingly attractive option for modern interiors.

Marble Jaali cutting manufacturers are playing a significant role in shaping the latest trends in architectural design. Marble jaali or latticework, has been a traditional element in Indian architecture for centuries and now, it is being reimagined for contemporary spaces. Manufacturers use advanced cutting techniques to produce intricate patterns that add an air of sophistication to any setting. These marble jaalis are often used as room dividers, window screens or even as decorative wall elements, providing both functionality and beauty.

The latest innovations in marble jaali cutting involve the use of CNC (Computer Numerical Control) machines, which allow for highly detailed and precise designs. These cutting-edge machines can produce patterns that were once thought impossible, bringing new dimensions to marble work. Manufacturers ofmarble jaalicutting are now catering to both traditional and modern tastes, with designs ranging from geometric patterns to floral motifs. The resurgence of marble jaali in interior design is contributing to the overall appeal of marble 3D wall panelling, as both complement each other beautifully in many projects.

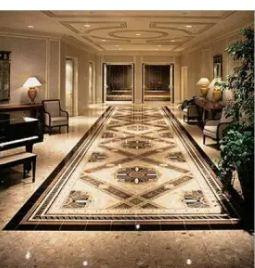

Another trend gaining traction in luxury interior design is the use of marble inlays. Marble floor inlay manufacturers are witnessing a surge in demand as homeowners and businesses alike seek to incorporate intricate marble patterns into their flooring. These inlays involve the precise placement of various coloured marble pieces to create stunning designs, often resembling works of art. The technique has been used for centuries in palaces and grand buildings and today, it is finding its way into modern homes and commercial spaces.

The beauty of marble floor inlays lies in their ability to elevate the overall look of a room. Whether it is a bold centrepiece for a grand foyer or subtle accents in a living room, these inlays can be customized to fit any aesthetic. Manufacturers ofmarble floor inlay are using a combination of traditional craftsmanship and modern technology to produce these intricate designs, ensuring both precision and artistry. As marble inlays continue to gain popularity, they are being paired with marble 3D wall panels, creating a cohesive and luxurious design scheme that is both timeless and modern.

One of the key advancements driving the marble industry forward is the use of CNC technology. Marble CNC work involves the use of automated machines to cut and carve marble with unparalleled precision. This technology has revolutionized the way manufacturers approach marble design, allowing them to create intricate patterns and textures that were once impossible to achieve by hand. Whether it is for wall panelling, jaali cutting or floor inlays, CNC technology is enabling manufacturers to push the boundaries of what’s possible with marble.

The use of marble CNC work is particularly important in the production of 3D wall panels, as it allows for the creation of complex textures and designs that add depth and dimension to any space. Manufacturers are now able to produce custom designs that cater to individual client needs, ensuring that each project is unique. This technology is not only making marble more accessible but also more versatile, allowing designers to experiment with different patterns, shapes and sizes to achieve their desired look.

As the demand for luxury interior solutions continues to grow, so too does the need for innovative manufacturing techniques. Marble 3D wall panelling manufacturers, along with experts in marble jaali cutting, floor inlays and CNC work, are at the forefront of this trend, providing designers and homeowners with the tools they need to create stunning spaces. From intricate jaali designs to custom floor inlays, marble is proving to be a versatile and timeless material that can be adapted to suit any aesthetic.

With companies like Zion Decors leading the way in Delhi, the future of marble design looks bright. The combination of traditional craftsmanship and modern technology is allowing manufacturers to push the boundaries of what is possible with marble, creating beautiful and functional designs that are sure to stand the test of time. Whether you are looking to add a touch of luxury to your home or make a bold statement in a commercial space, marble 3D wall panelling, jaali work and floor inlays offer a range of possibilities for creating a truly unique and elegant interior.